+86-0373-3696559

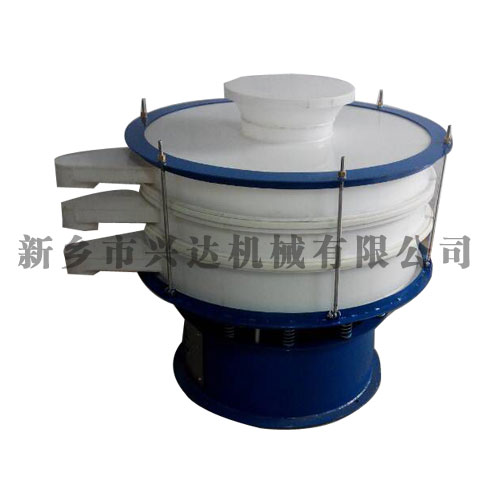

Product Description:Polypropylene vibrating screen

Product features:The purpose of polypropylene vibrating screen is to eliminate the chemical reaction between some special materials and metal. The screen frame, screen and cleaning device are made of non-metallic materials.

The purpose of polypropylene vibrating screen is to eliminate the chemical reaction between some special materials and metal. The screen frame, screen and cleaning device are made of non-metallic materials.

Product parameters:

A single series of sieving machine can be equipped with one to five layers of screen, which can accurately and continuously separate two to six particle sections at the same time; the classification accuracy is more than 95%.

High precision screen can quickly remove large or small particles with low percentage content in the process of high flow material treatment. Most of them are single-layer. The advanced design of the series of vibrating screen filters, with high efficiency and quality of impurity removal, can reach more than 98% accuracy.

Polypropylene shale shaker can quickly remove the insoluble large particles in all kinds of slurry, which is mostly used in single layer. This series of specially designed screening filters can filter up to 20 cubic meters per hour.

Product features:

Mesh anti blocking - the automatic cleaning and plugging device designed by our company can effectively reduce the blocking phenomenon;

Single layer or multi-layer self selection - it can carry out two to four levels of sorting or filtering at the same time;

High efficiency and accurate screening - all incoming materials are discharged automatically, and there is no material in the machine. The polypropylene vibrating screen with the same screen surface has larger capacity than other screen machines. The company's well-developed screen holder can make the percentage of materials on screen out of the machine less than that of other machines of the same type;

Convenient screen replacement - Polypropylene vibrating screen machine has a variety of grid structures according to different needs; one of them reduces the screen replacement time to 3-5 minutes, saving 30-60 minutes compared with other types of screen machines. Longer screen life and higher efficiency;

No mechanical transmission of vibration - the new vibration source of polypropylene shale shaker produces strong and stable three-dimensional vibration, and the equipment can be installed in any required position and easy to move;

Economic and environmental protection -- the whole machine and screen have long service life, low energy consumption, low maintenance cost, high efficiency and easy replacement, which make the equipment economical and affordable. Low noise, totally enclosed, outstanding environmental protection performance.

| Product Name: | |

| Tel: | |

| Note: | |

| Captcha: |

|

- UP:NONE;

- NEXT:Rotary vibrating screen